One-stop on-demand manufacturing service, our manufacturing network covers more than 10,000 manufacturers in China and overseas, which can provide the production capacity you need to help you carry out prototyping and production.

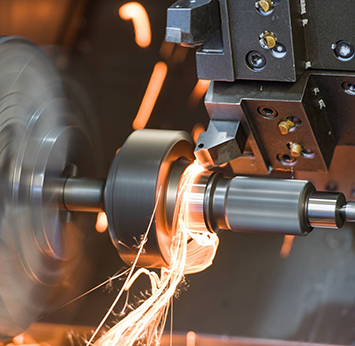

Our processed products are widely used in Aerospace & Defense, Robotics & Machine-Building, Industrial Production, Precision Instrument, Electronics, Energy and Precision Manufacturing for Every Industry.

Our products are widely used in railway, highway, tunnel, subway, coal mine, geology, metallurgy, water conservancy and other industries.

Because laser technology has the characteristics of low welding heat input, little influence on the welding heated area and not easy to deform, it has received special attention in the field of aluminum alloy welding. But on the other hand, due to its own...

View News Details

Diaphragms made of plastic or rubber are very important components in vacuum pumps. Because the diaphragm must form a tight seal between the pump's inner and outer chambers for efficient pumping. The edge of the diaphragm must be smooth and actinic,...

View News Details

It is no longer a problem for laser cutting machines to cut steel plates below 10mm thick. But if you want to cut thicker steel plates, you often resort to high-power lasers with an output power exceeding 5kW, and the cutting quality is also significantly...

View News Details

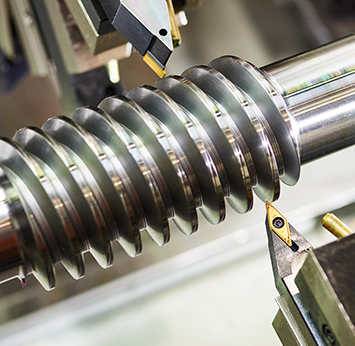

1. What is a slender shaft?Shafts whose length-to-diameter ratio is greater than 25 (ie L/D>25) are called slender shafts. Such as the screw on the lathe, the feed rod, etc.2. the processing difficulty of the slender shaft:Due to the poor rigidity of t...

View News DetailsConduct in-depth cooperation with more than 500 foreign buyers, and maintains long-term cooperation with more than 1,000 domestic advanced manufacturing suppliers.